Understanding the Impact of China CNC Lathe Turning Parts Manufacturers

CNC lathe turning parts are critical components in modern manufacturing processes, particularly in industries that require precision machining. Manufacturers across the globe rely on these parts for their machinery, making the selection of a reliable supplier essential. In this article, we delve deep into the realm of China CNC lathe turning parts manufacturers and explore their influence on the global manufacturing landscape.

The Significance of CNC Machining in Manufacturing

Computer Numerical Control (CNC) machining has revolutionized the way components are produced. By integrating advanced technology with traditional machining methods, CNC machining offers unparalleled precision, efficiency, and flexibility. Here's why CNC machining is essential in modern manufacturing:

- Precision: CNC machines can produce parts with incredible accuracy, often to within a thousandth of an inch.

- Consistency: Once programmed, CNC lathes can produce thousands of identical parts without variation.

- Efficiency: Automated machining speeds up production and reduces human error, leading to shorter lead times.

- Complexity: CNC technology allows manufacturers to create intricate designs that would be impossible with traditional methods.

China's Role in Global CNC Machining

China is a leading player in the global CNC machining industry, thanks to its robust manufacturing infrastructure and skilled workforce. The country's CNC lathe turning parts manufacturers are known for their ability to deliver high-quality components at competitive prices. Here are some reasons behind China's dominance:

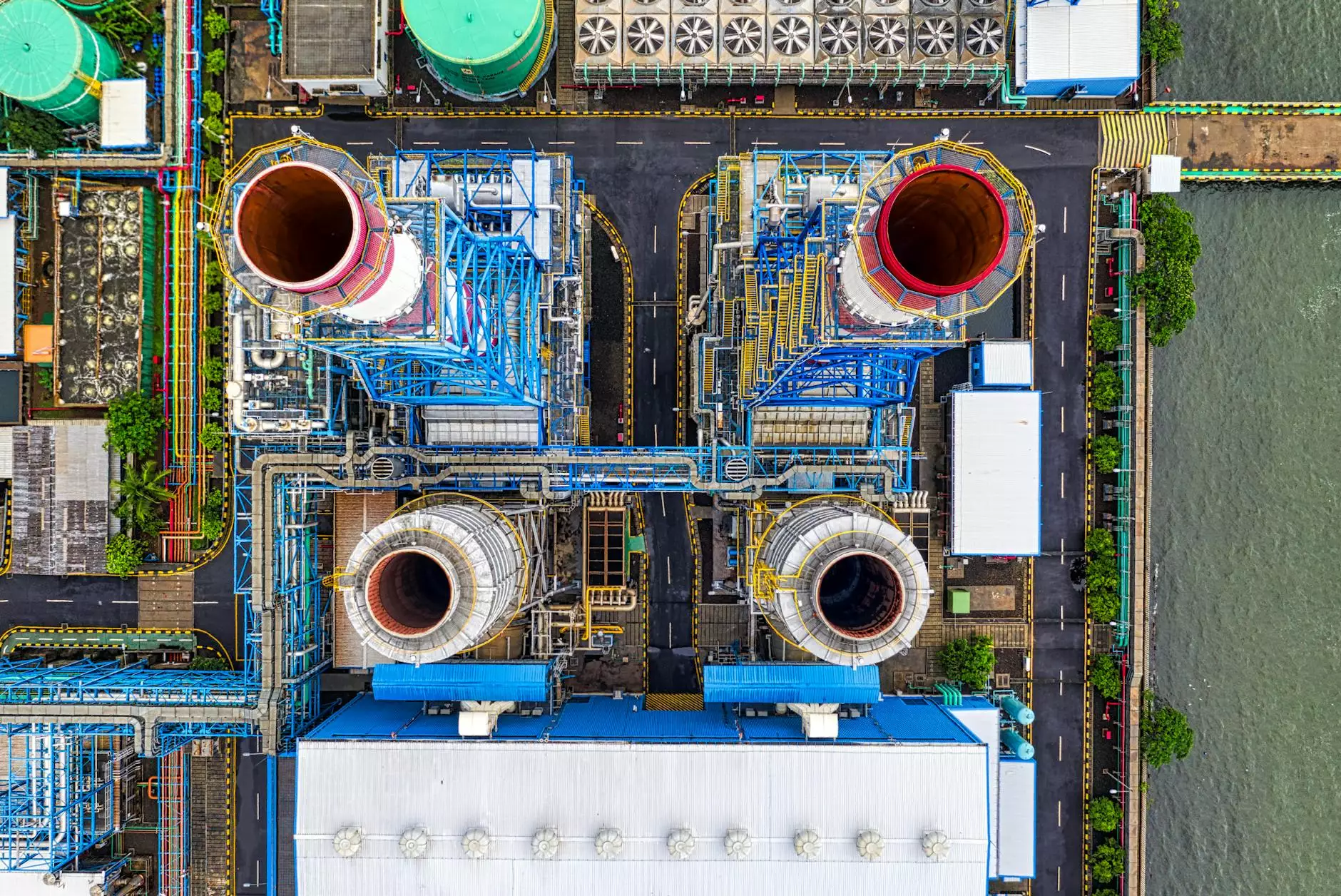

1. Advanced Manufacturing Facilities

The backbone of China's success in CNC machining lies in its well-established manufacturing facilities. Equipped with state-of-the-art machinery, these factories employ cutting-edge technologies like:

- High-Precision CNC Lathes: Designed for efficiency and precision, these machines are essential for producing intricate turning parts.

- Automated Quality Control Systems: Ensuring that every part meets rigorous quality standards through real-time monitoring.

- Robotic Automation: Enhancing production speed and consistency while reducing labor costs.

2. Skilled Workforce

The availability of a large pool of skilled technicians and engineers enables Chinese manufacturers to maintain high standards of quality and innovation. Continuous training programs ensure that the workforce is well-versed in the latest machining technologies and practices.

3. Cost-Effectiveness

China offers a unique combination of low labor costs and high productivity, making it a cost-effective choice for many businesses. This economic advantage allows for competitive pricing while maintaining quality standards.

Key Attributes of Leading CNC Lathe Turning Parts Manufacturers

When considering potential suppliers, it’s crucial to identify what sets renowned China CNC lathe turning parts manufacturers apart. Here are key attributes that define industry leaders:

1. Quality Assurance

Top manufacturers implement strict quality assurance protocols, often obtaining certifications such as ISO 9001, which ensure their products meet international quality standards. Regular audits and tests guarantee that every part produced is of the highest quality.

2. Customization Capabilities

Customization is vital in meeting specific client needs. Leading manufacturers offer:

- Tailored Solutions: The ability to create parts according to individual specifications.

- Material Options: Offering a wide variety of materials to cater to different applications, from aluminum and stainless steel to brass and plastic.

- Design Assistance: Supporting clients in optimizing designs for manufacturing efficiency.

3. Technical Expertise

Understanding the technical aspects of CNC machining is crucial for manufacturers. The best in the field invest in R&D to stay ahead of technological advancements and continually improve their processes.

Application of CNC Lathe Turning Parts Across Industries

The versatility of CNC lathe turning parts makes them indispensable in various industries. Here are some key sectors that benefit from these components:

1. Automotive Industry

In the automotive sector, precision components are vital for assembly and performance. CNC turning parts are used in:

- Engine blocks

- Shafts

- Transmission housings

- Brake components

2. Aerospace Industry

The aerospace industry demands the highest quality standards due to safety regulations. CNC lathe turning parts are critical for:

- Structural components

- Engine parts

- Landing gear

- Fuel system components

3. General Manufacturing

Many other industries, including electronics, medical, and construction, rely on CNC lathe turning parts for machinery, tools, and equipment, ensuring operational efficiency and product longevity.

Choosing the Right CNC Lathe Turning Parts Manufacturer

Selecting the right manufacturer is a critical step for businesses seeking to optimize their production processes. Here are some tips for making the right choice:

1. Research and Reviews

Conduct thorough research on potential manufacturers. Look for customer reviews and ratings that reflect their reputation in the industry. Websites like deepmould.net can offer insights into their capabilities and services.

2. Ask for Samples

Before committing to a large order, request samples to assess quality firsthand. This step is crucial in ensuring that the manufacturer meets your quality standards.

3. Communication and Support

Effective communication is vital for a successful partnership. A manufacturer that is responsive and supportive will be easier to work with, particularly in addressing issues that may arise during production.

The Future of CNC Machining in China

The future of CNC machining in China looks promising, with continuous advancements being made in terms of technology and processes. As manufacturers adapt to emerging trends, they are likely to improve their capabilities, including:

- Integration of AI and Machine Learning: To enhance efficiency and predict maintenance needs.

- Sustainability Initiatives: Adopting eco-friendly practices to minimize waste and energy consumption.

- Expansion of Smart Manufacturing: Leveraging the Internet of Things (IoT) to create smart factories that optimize productivity and resource management.

As these developments unfold, businesses around the world will continue to benefit from the expertise of China CNC lathe turning parts manufacturers, solidifying China's position as a leader in the global manufacturing sector.

Conclusion

In conclusion, the impact of CNC lathe turning parts manufacturers in China cannot be overstated. Their contributions to various industries underscore the importance of precision, efficiency, and quality in manufacturing. As the industry evolves, it is certain that these manufacturers will play a pivotal role in shaping the future of production capabilities worldwide.